I hesitate to call the inner fender extensions "splash guards" because there's rubber inner fender "splash guards" used on some of the 2nd gen Firebirds that are stapled to the inner fender where the upper A arm opening is.

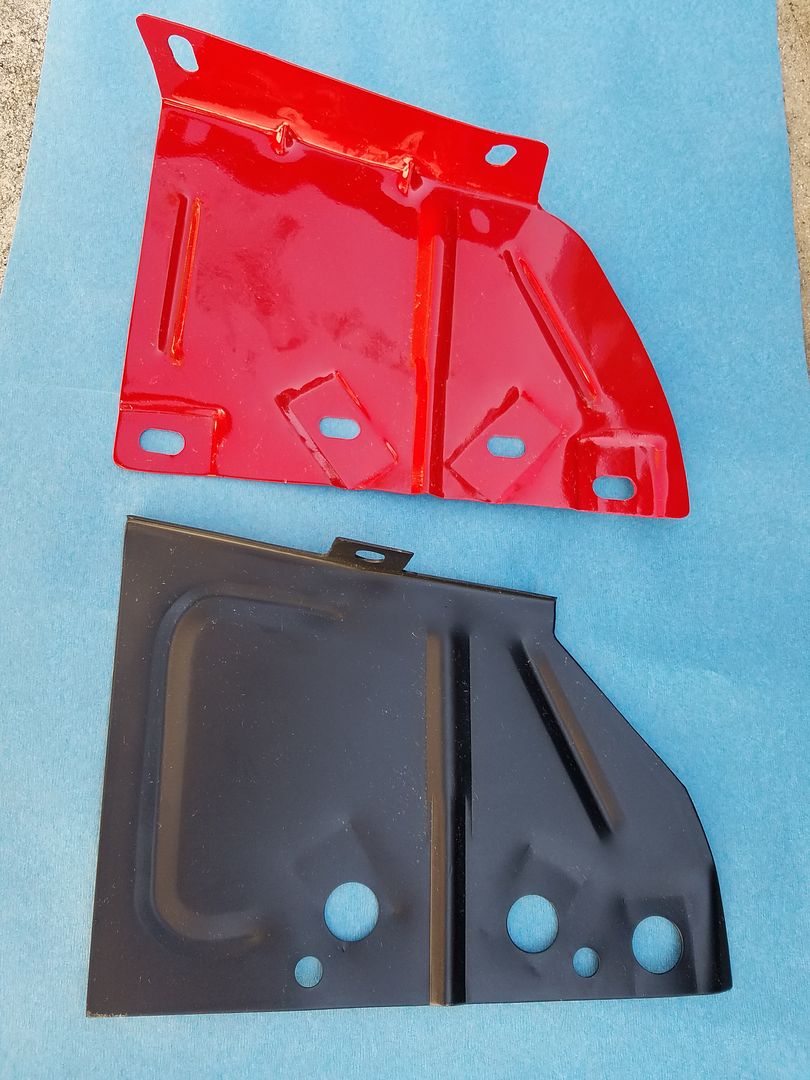

I started making the 77-78 and 79-81 versions when I got requests for them because they weren't being reproduced and 77-81 owners were told to use the 70-76 reproductions and modify as necessary to try and make them fit. They do look different so those doing correct "restoration" type builds wanted a better fitting correct looking piece. The bead rolling in the center of the 77-78 conforms to a bead rolled in the other parts like the inner fender. I think Aus78Formula has some good pics of how they fit together. The stamping for the U nuts is angled differently and centered differently on the mounting holes. A lot of people think the stamps were just poorly done because the stamps are offset different ways on the bolt holes but they are like that for a reason. The area that bolts to the core support is different also as you can see in the pic below.

Dunno how much you paid for the 77-78 style ones you have but you can probably flip them and have enough money to buy a set of more original looking 70-76 repros.

While they're often referred to and thought of as splash guards they're also important to aerodynamics and help maintain a pressure difference between the front and back sides of the radiator. Not having the inner fender extensions can increase the air pressure in the engine compartment making it more difficult for the radiator and fan to cool the engine coolant and noticeably reduce AC performance.

I can (and have) made 70-76 inner fender extensions but I can't make them as cheap as suppliers can have them stamped out over in China. I'm a small batch operation using higher quality steel in the original 18 gauge and making them by hand where they can use a punch press and cheaper possibly thinner steel. I make the 77-81 versions more as a favor to the Firebird community, I loose money on every one I sell because of the time involved in making them even though I sell them for more than the 70-76 repros sell for. So I don't promote them and if one of the "big guys" starts having them reproduced overseas it won't hurt my feelings a bit.

Pic below is of 70-76 style and a 77-78 style. I also made the 70-76 in the pic.

I'm not sure what gauge steel DSE uses in the cowl mounts but I'd suspect they may have beefed them up over stock specs. So my reinforcements might be overkill, I'd be interested to know what gauge they're using. You should however consider a set of PTFB Pro G braces and a set of my upper cowl supports to go with them based on the Pro Touring style build I've seen you talk about on other forums.

I saw your builder question on another forum also. I work on upgrade projects and build cars for people. Mostly for locals and occasionally someone ships a car down. I'm cheap comparatively so the shipping cost is often covered by the price difference plus those who dealt with me when I lived up North have peace of mind I'm not going to screw them over. Like some of the others I only do jobs by the hour, it's just too hard to "guess" an estimate because every car is different and usually some things get changed along the way by the owner anyway. I work mostly alone and for some types of jobs have other experienced old guys like me help to make the job go quicker. I have an old body guy help with large body/paint jobs and an old ASE master tech help on some of the more extensive mechanical stuff. I like to get cars in, get them done, and get them out. I don't understand why soo many shops keep cars like they're hostages (although I worked in shops that did that). Below is a pic of a 70 TA that got shipped down from GA recently by someone I dealt with before when we both lived in CT. It was here for sub frame repair, complete replacement of all steering and suspension components, solid body mounts, and bolt in sub frame connectors. Was here about two weeks.

I'm not trying to sell you on shipping your car down, can't take it now anyway. Just figured I'd babble during my break and maybe someone local will read this and perhaps inquire about work in the future. I'm doing trunk pan, drop offs, frame rails, torque boxes and fabricating some floor pan sections on a 67 Camaro RS SS conv. this week soo as soon as I post pics, back to the shop I go!>>>